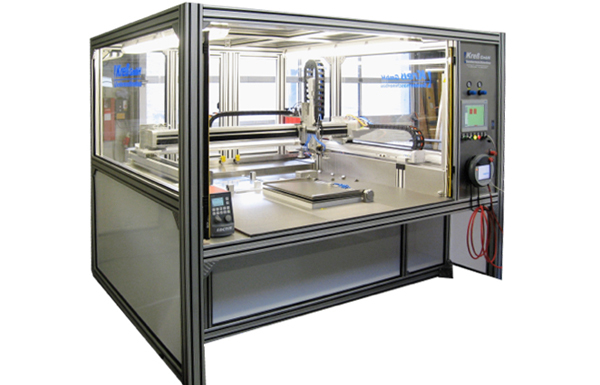

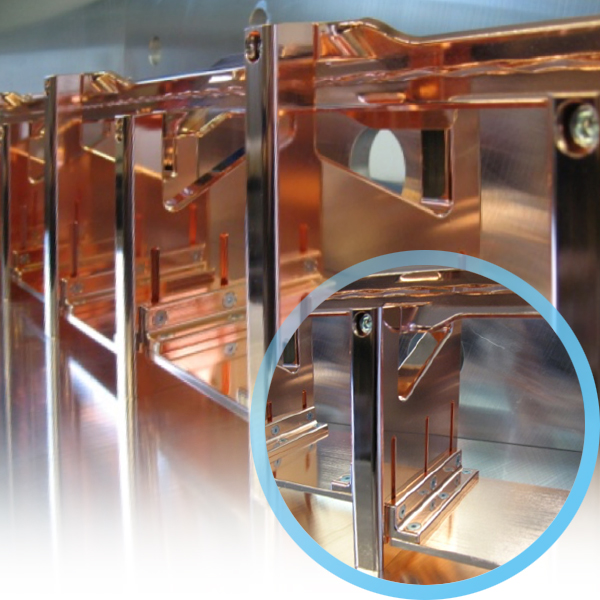

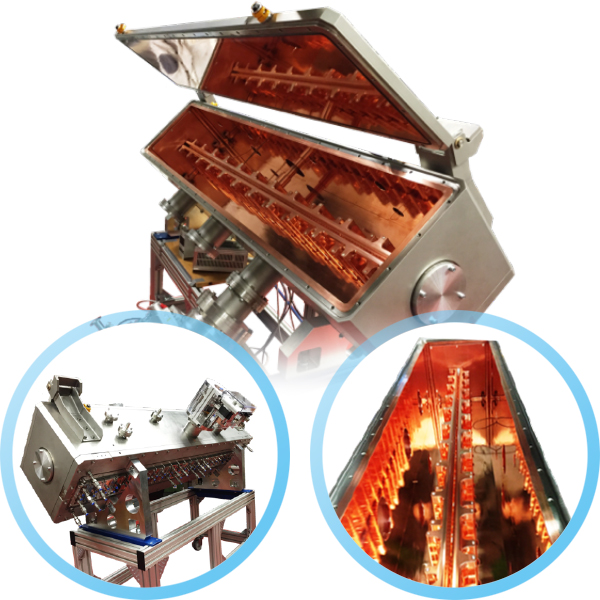

Kreß GmbH has developed new electrode stems and tuning plates for a new generation of RFQ accelerators for high-performance applications with high beam currents and

RF continuous operation (CW). These stems and tuning plates have already been used in the proton RFQ which Kreß GmbH built for the LANSCE project in the Los Alamos National Laboratory.

Calculations with CST Microwave Studio and ANSYS at the Los Alamos National Laboratory have shown that the new tuning plates ensure an excellent electrical and thermal contact

between the tuning plates and stems. In addition on this new system, no forces have an effect on electrode stems. With conventional systems these can have a negative effect on

the electrode geometry and on the beam dynamics.

The design of the tuning plates is the intellectual property of Kreß GmbH and is protected as a registered design.

Customers

- Los Alamos National Laboratory